AAC Block Plant in Bangalore:

Headquartered in Ahmedabad, Gujarat, Excellent En-Fab Incorporation is a prominent manufacturing hub in India for process and construction equipment.

“Excellent En-Fab Incorporation” was established in 2010 with the aim of providing high-pressure autoclaves to AAC block manufacturers

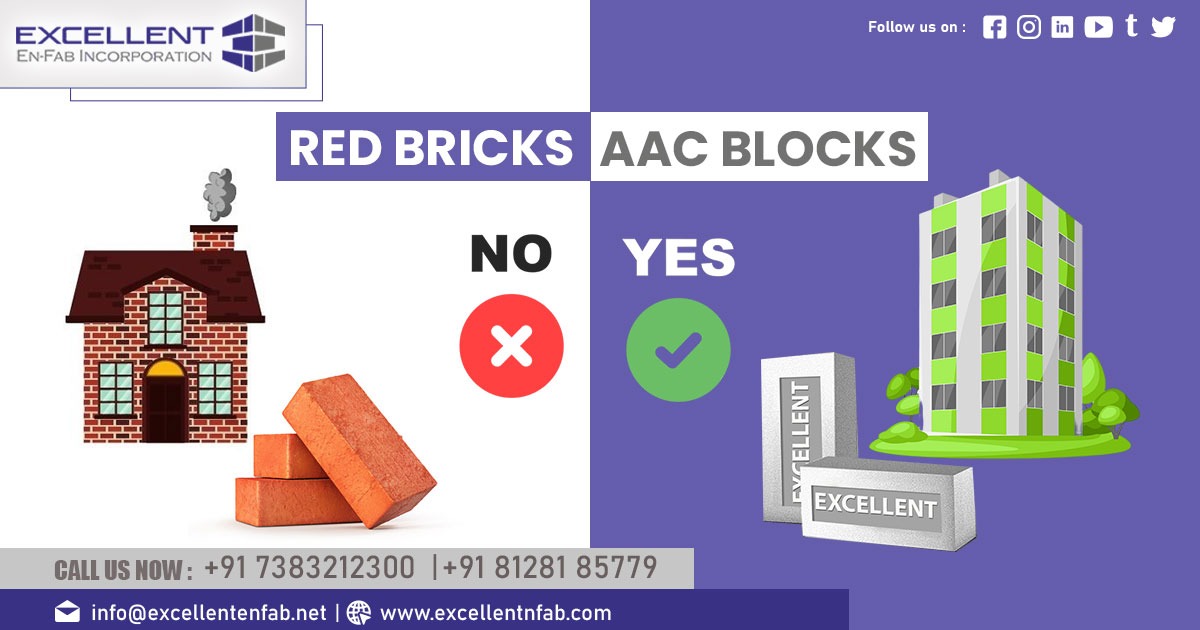

AAC (Autoclaved Aerated Concrete) block plants represent a significant advancement in the construction industry.

These plants are committed to producing AAC blocks, which are lightweight and eco-friendly alternatives to traditional bricks.

How Does AAC Block Plants Work?

AAC block plants are designed to manufacture AAC blocks, which are renowned for their lightweight and insulating properties.

Raw Material Preparation: Precise proportions of sand, cement, lime, and aluminum powder are mixed to create a slurry.

Molding: The slurry is poured into molds, where it begins to expand and rise due to a chemical reaction.

Curing: The molded blocks are placed in an autoclave, a high-pressure steam chamber, where they undergo curing. This process ensures that the blocks achieve their final strength and insulating properties.

Quality Control: The blocks undergo quality checks to ensure they meet the required standards.

Components of AAC Block Plants

AAC block plants consist of several key components:

Mixing Unit

This unit combines sand, cement, lime, and aluminum powder to form the slurry used in block molding.

Molding Machine

The molding machine creates the initial shape of the AAC blocks.

Cutting and Shaping Equipment

These machines cut the cured blocks into precise dimensions.

Quality Control Systems

Quality control measures are in place to ensure that the produced blocks meet industry standards.

We Provide AAC Block Plant in Bangalore Including Peenya, Doodannakundi, Rajaji Nagar, DDK Industrial Area, Petechannappa, Kamakshipalya, Kiadb, Dobbaspet, Bidadi, Dyavasandra, Jigani, Kumbalgudu, Mahadevpura, Rajaji nagar and kamakshi palya, Attibele Etc.