AAC Block Plant in Assam:

Excellent En-Fab Incorporation:

Based in Ahmedabad, Gujarat, it is a prominent player in India’s Process & Construction Equipment Manufacturing Hubs.

Established in 2010, with a focus on supplying high-pressure autoclaves tailored for AAC (Autoclaved Aerated Concrete) block plants.

AAC Block Manufacturing Process:

A unique process produces AAC blocks, involving the mixing of finely ground sand, cement, lime, and aluminum powder.

Autoclaving, a high-pressure steam curing process, results in the formation of aerated concrete with a porous structure.

Plant Components:

Mixing and Casting Section: Precise blending of raw materials to create a homogenous slurry, poured into molds for block formation.

Curing Section: Blocks undergo autoclaving, a high-pressure steam curing process, enhancing their strength and durability.

Cutting and Packaging Section: After curing, blocks are cut into specific sizes using specialized equipment and then packaged for distribution.

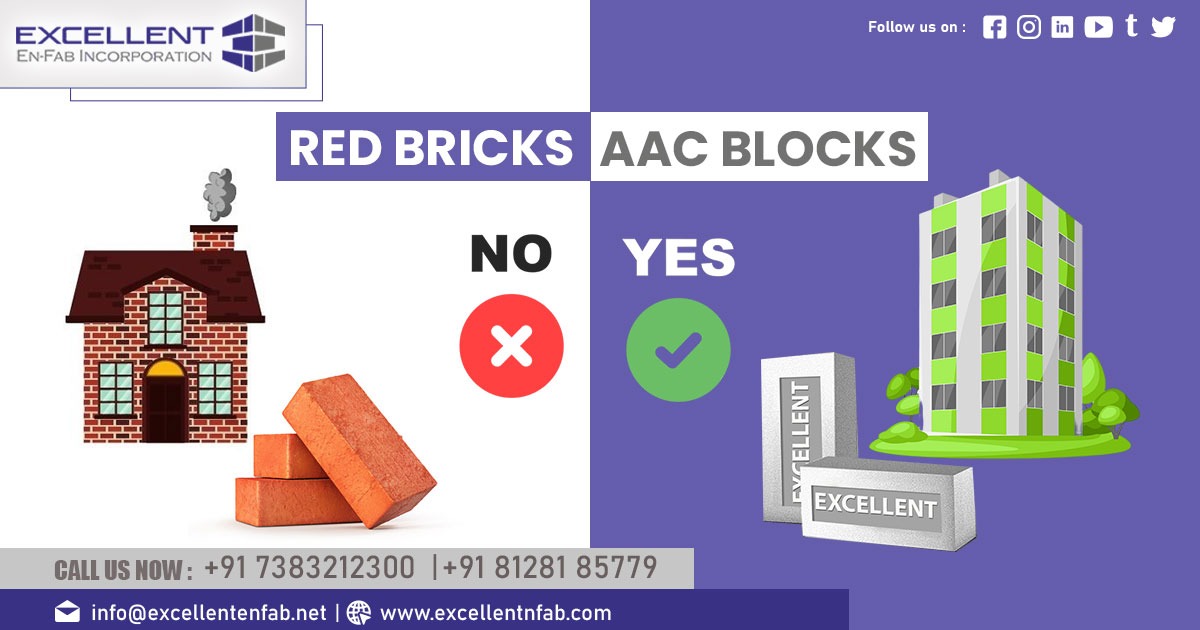

Advantages of AAC Blocks:

Lightweight: Significantly lighter than traditional concrete blocks, facilitating easier handling during construction.

Thermal Insulation: The porous structure provides excellent thermal insulation, contributing to energy-efficient buildings.

Fire Resistance: Exhibits high fire resistance, enhancing structural safety.

Sound Insulation: Porous nature contributes to effective sound insulation.

Applications of AAC Blocks:

Find applications in various construction projects, including residential, commercial, and industrial buildings.

Commonly used for load-bearing walls, partitions, and as a substitute for traditional bricks.

Excellent En-Fab provides AAC Block Plant in Assam, covering key locations such as Dhuburi, Dibrugarh, Dispur, Guwahati, Jorhat, Nagaon, Sivasagar, Silchar, Tezpur, and Tinsukia.